What is Resin Bound?

The Ultimate Guide to Resin Bound Surfacing

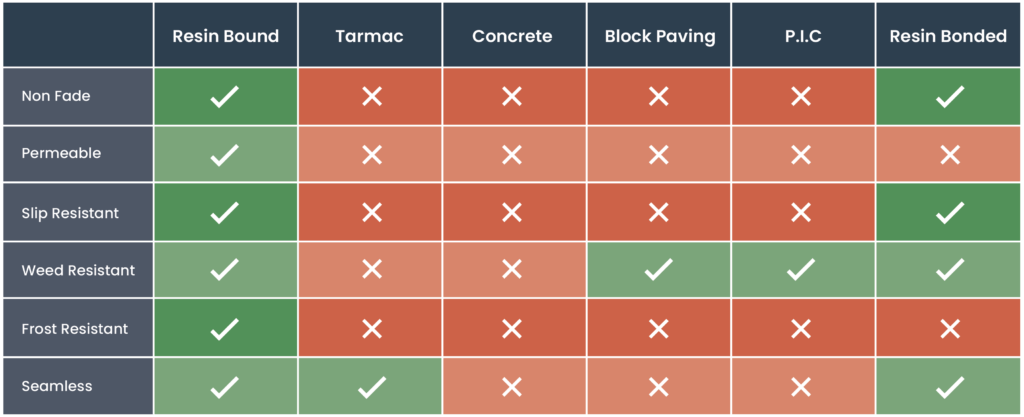

If you’re considering a modern, low-maintenance alternative to traditional paving, resin bound surfacing is a popular choice. Known for its seamless finish, permeability and aesthetic appeal, they offer a long-lasting option for driveways, patios, pathways and commercial spaces.

But what exactly is resin bound surfacing, how is it installed, and what makes it stand out from other paving solutions like loose gravel, concrete or tarmac? In this guide we’ll break it down and explain why more homeowners and businesses are switching to resin bound systems.

What is Resin Bound?

Resin bound is a type of surfacing made by mixing natural stone aggregates with a clear resin binder. The two are blended in a forced action mixer before being applied to a prepared surface. This creates a smooth, hard-wearing and permeable resin bound finish that allows water to drain through, helping to reduce surface water build-up and meet Sustainable Drainage System (SuDS) requirements.

The result is a decorative, practical surface ideal for resin driveways, patios, pathways, and even commercial spaces such as public walkways and car parks.

Why Choose a Resin Bound System for Your Driveway or Patio?

Resin bound systems combine visual appeal with practical performance. Here’s why they’re such a popular choice:

Key Benefits of Resin Bound Surfaces:

- Long-lasting Colour and UV Stability

Unlike tarmac or concrete, which can fade and weather over time, resin bound surfaces maintain their colour. UV-stable resin binders prevent yellowing and deterioration, keeping your driveway or patio looking great for years.

- Permeability & SuDS Compliance

The porous structure of resin bound surfacing means water naturally drains through the surface, preventing puddles and reducing flood risks. For driveways and patios, this can remove the need for planning permission in line with SuDs regulations.

- Slip Resistance & Safety

Resin bound surfaces offer excellent slip resistance. Their textured, seamless finish makes them safer underfoot in wet or icy conditions compared to smoother surfaces like concrete.

- Weed Resistance & Easy Maintenance

Bound gravel stays locked in place, with no loose stones to scatter or gaps where weeds can grow. Maintenance is minimal, occasional sweeping and jet washing are all that’s needed to keep the surface clean.

- Durable in All Weather Conditions

Resin bound surfaces are designed to withstand the elements. Their frost-resistant properties prevent cracking in cold temperatures, while their tough resin binder resists wear and tear from heavy foot traffic or vehicles.

Where is Resin Bound Surfacing Used?

Resin bound paving is incredibly versatile. It’s commonly used for:

-

Driveways: Offering kerb appeal with a smooth, durable surface.

-

Patios and Gardens: Creating high-quality, safe and weed-free outdoor spaces.

-

Commercial Premises: From car parks to office forecourts, resin bound surfacing provides a polished, low-maintenance finish.

-

Public Spaces: Footpaths, parks, and public walkways where drainage and safety are key.

How is Resin Bound Installed?

The installation process requires precision and expertise. Here’s a quick overview of how professionals lay a resin bound surface:

- Base Preparation – A solid, porous sub-base (such as asphalt or compacted stone) is prepared to ensure stability and proper drainage. Any cracks or imperfections are repaired to create a smooth base layer.

- Mixing the Resin and Aggregate – Using a forced action mixer, aggregates are blended with high-quality resin to achieve a consistent mix.

- Application & Troweling – The mixture is poured and evenly spread using a hand trowel to create a smooth, even surface. Skilled trowelling ensures there are no uneven patches or loose stones.

- Curing Time – The surface is left to set for around 24-48 hours before it can be used.

Resin Bound vs. Resin Bonded: What’s the Difference?

Many people confuse resin bound with resin bonded surfaces, but they are quite different in composition and performance:

Resin Bound:

-

Fully permeable, allowing water to drain through.

-

Smooth and seamless finish.

-

Made by mixing aggregates with resin before application, ensuring each stone is coated.

-

Ideal for driveways, patios, and pathways that require SuDS compliance.

Resin Bonded:

-

Non-permeable, meaning water runs off the surface rather than draining through.

-

Coarser, textured finish.

-

Involves applying resin to a surface first, then scattering loose aggregate on top.

-

Often used for decorative finishes where permeability isn’t required.

Long-Term Benefits of Resin Bound Driveways and Patios

Investing in resin bound surfacing gives you more than just a good-looking driveway or patio. It’s a long-term solution designed for:

-

Durability: Built to withstand cars, foot traffic, and all weather conditions.

-

Low Maintenance: Say goodbye to weeds, cracks, and loose gravel.

-

Eco-Friendly Drainage: Reduces the risk of flooding by letting water pass through naturally.

-

Aesthetic Versatility: Choose from a wide range of stone colours and blends to suit your property. View our resin bound surfaces gallery to see examples of resin bound driveways we’ve installed.

Is Resin Bound Surfacing Worth it?

Resin bound paving is a great choice for any property, offering a combination of durability, low maintenance and a polished look. Its permeable surface naturally manages water runoff, helping to prevent puddles and drainage issues. Built to last, it keeps its smooth finish for years and suits everything from large resin driveways to small garden paths.

At Ace Resin, we use only the highest quality UV-stable resin binders and carefully selected aggregates to deliver beautiful, durable resin bound driveways, patios, and commercial surfaces. Whether you’re upgrading an existing surface or starting from scratch, our experienced team will help you choose a resin bound system that complements your space and stands the test of time.

Donna Jones

HEAD OF SALES

Donna Jones, Head of Sales at Ace Resin, has 40 years of construction experience, including two decades at the forefront of resin-bound surfacing. Passionate about innovation and sustainability, she plays a key role in supporting contractors across the UK, helping them enhance their projects with premium, eco-friendly solutions and expert training.