All Prices include V.A.T.

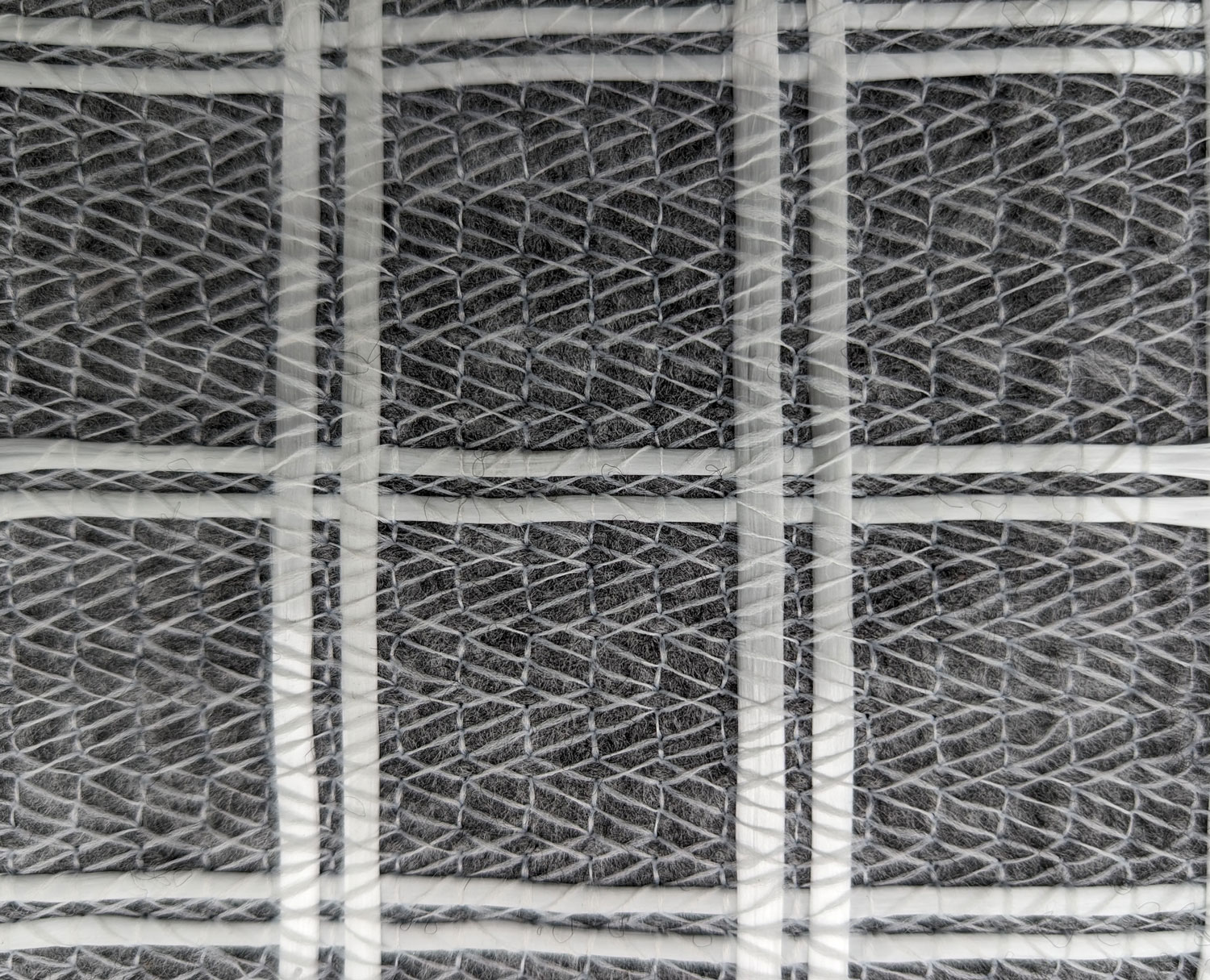

Ace ResiMesh

£960.00 inc. V.A.T

Price per 100m roll.

- Crack Mitigation: Ideal for overlaying cracked concrete or tarmac, significantly reducing the risk of reflection cracking.

- Ease of Installation: The supple fabric design stays flat with no ripples when rolled out and is easy to cut and handle on-site.

- SuDS Compliance: Allows water to permeate through, ensuring Sustainable Urban Drainage Systems (SuDS) compliance.

- Section Reduction: Can be installed directly onto MOT Type 1 or 3, eliminating the need for additional layers.

- Thickness Efficiency: No need to increase the depth of the resin bound surface during installation.

- Ground Stability: Suitable for installation onto unstable ground, reducing the risk of cracking.

Overview:

The Ace ResiMesh system offers a revolutionary, faster, and more cost-effective solution for resin bound surfacing installations. This system streamlines installation by eliminating the need for a structural base, thereby accelerating project completion and reducing labor costs. Ace ResiMesh is a specially engineered reinforced composite that serves multiple functions, such as an isolation layer for overlay installations or as a replacement for traditional structural sub-bases, negating the requirement for tarmac or concrete. It is particularly effective in mitigating the risk of cracking.

Contractor-Friendly Solution:

Ace ResiMesh is designed to be user-friendly, enabling contractors to manage the entire resin bound installation process independently, reducing the reliance on specialized professionals for tarmac, concrete, or other structural base installations.

Functional Benefits:

- Reinforcement (R): Enhances structural integrity

- Stress Relief (STR): Reduces stress within the pavement

- Specification (S): Prevents contamination from soil

Composition:

- Material: Glass filament grid structure

Additional information

| Weight | 40 kg |

|---|---|

| Dimensions | 10000 × 1000 × 2 mm |

Committed to delivering 'best in class' quality

Product FAQ's

What’s the difference between a resin bound driveway and a resin bonded driveway?

Resin Bound

Resin bound is an eco-friendly, highly porous paving solution for ground surfacing. It is a choice of decorative aggregates mixed with specialist resins then hand trowelled to give a flat smooth surface suitable for driveways, paths and patios.

Resin Bonded

Resin bond is laid in a different manner to resin bound materials. It involves applying a layer of resin to the existing surface, which aggregates are then scattered in to the top of. This gives a non-porous surface, which has a coarser finish and leaves a certain amount of loose stone on the final surface.

How long will a resin bound driveway last?

A resin bound driveway is a strong and durable surface, that is resistant to weather conditions. Comparable products like Tarmac or Asphalt can soften in the summer heat and freeze in cold of winter, they will also be damaged by UV light. Resin is much more stable than these alternatives performing well year round in some of the UK’s worst weather. Our driveways come with a 10 year guarantee and can last to a good standard for 25+ years.

Can I lay a resin driveway over my existing driveway?

This depends on the type and condition of your existing driveway. However, it should be laid on an appropriate sub-base of either asphalt or concrete.

Do I need planning permission for a resin driveway?

If you have an existing driveway then planning permission will not be required. For any newly installed driveways or extensions planning permission is required for surfaces such as traditional block paving, flags and tarmac.